Why Recycle Batteries

Batteries contain metals, liquids, and other materials that are flammable, toxic and hazardous to the environment if they are not handled and disposed of properly. Those materials can include lead, zinc, nickel-cadmium, sulfuric acid, mercury, plastic, lithium, and others. When you use an R2 Certified recycler like Modern Waste, you are ensuring that the dangerous materials contained in the batteries are not making their way into the land fill where they can seep into local waterways.

Battery Recycling Services We Offer

Modern Waste provides all aspects of battery recycling with emphasis on compliance and logistics challenges. Services include, but are not limited to:

Battery Types We Recycle

- Alkaline Batteries

- EV Batteries

- Lithium-Ion (L-ion) Batteries

- Lithium Primary Batteries

- Lead Acid Batteries

- Mixed Batteries

- Nickel Cadmium (NiCd) Batteries

- Nickel Metal Hydride (NiMh) Batteries

- Rechargeable Batteries

- Various Other Types of Batteries

Battery Recycling Process

Each type of battery has different processes for material recovery and recycling. Batteries like lithium ion tool batteries may be handled differently than lithium ion cell phone batteries even though they are the same chemistry. Tool batteries are made up of a group of smaller cells or smaller batteries put together. Those cells can be removed from the battery and tested individually. Cells that test to high enough standards can be reused and defective or substandard cells are sent for material recovery to make new products.

Sample Process

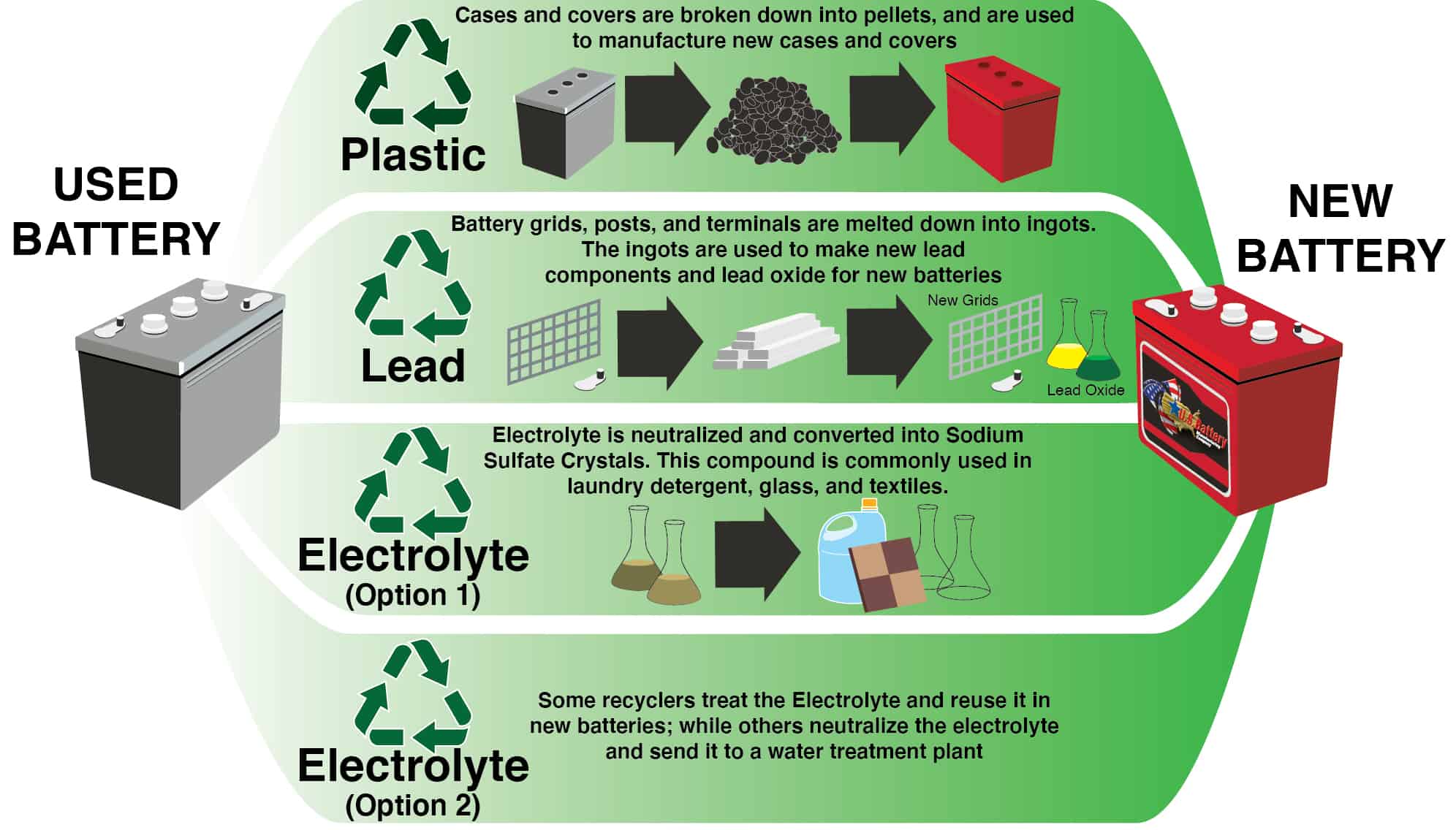

Whole Lead Acid Batteries are broken apart in a hammer mill shredder, a machine that beats the battery into pieces. The broken battery pieces are then placed into a vat, where the lead and heavy materials fall to the bottom and the plastic floats. The polypropylene pieces are removed and the liquids are drawn off, leaving the lead and heavy metals. Each of the materials goes into a separate recycling “stream”.

- Plastic pieces are washed, blown dry and sent to a plastic recycler where the pieces are melted together into an almost liquid state. The molten plastic is put through an extruder that produces small plastic pellets of a uniform size. The pellets are put back into manufacturing battery cases and the process begins again.

- Lead grids, lead oxide and other lead parts are cleaned and heated within smelting furnaces. The molten lead is then poured into ingot molds. After a few minutes, the impurities float to the top of the still molten lead in the ingot molds. These impurities are scraped away and the ingots are left to cool. When the ingots are cool, they’re removed from the molds and sent to battery manufacturers, where they’re re-melted and used in the production of new batteries.

- Old battery acid can be handled in two ways: The acid is neutralized with an industrial compound similar to household baking soda. Neutralization turns the acid into water. The water is then treated, cleaned, tested in a waste water treatment plant to be sure it meets clean water standards. The acid is processed and converted to sodium sulfate, an odorless white powder that’s used in laundry detergent, glass and textile manufacturing. Lead acid batteries are closed-loop recycled, meaning each part the old batteries is recycled into a new battery. It is estimated that 98% of all lead acid batteries are recycled.

How Does Modern Waste Help You?

Modern Waste makes it simple for you to have comprehensive and compliant Battery Recycling services that adhere to all applicable local, state and federal rules and guidelines.

1. We will provide the equipment you need

2. We will train you on what you need to know

3. We will come to you to pick up (or you can drop off)

4. We will record what we receive from you in our database

5. We will shred, wipe, recycle or dispose of your waste

6. We will provide certificates and reports as needed

Get a Quote

Additional Services

- Battery Sorting

- Battery Insulating and Packaging

- Battery Containers for Storage and Transportation

- Compliance and Logistics Consulting

- Pick-up, Transportation and Handling

- Proper Labeling and Signage

- UPS System Deinstallation and Recycling

- On-site EV Battery Safety-Tear-Down

Modern Waste Advantage

6 Steps to Success

Included With Every Service & Customer Compliance Need